In the realm of automotive engineering, safety remains a paramount concern, driving the development of advanced techniques and technologies. One critical aspect of vehicle safety is the ability to withstand impact during a collision. Crash tests are meticulously designed experiments that evaluate how well a vehicle can protect its occupants under various crash scenarios. These tests provide invaluable data, influencing both design and materials used in the vehicle’s construction.

Integral to enhancing vehicle resilience is the concept of the crash cell, a structural component specifically engineered to absorb and dissipate energy during an accident. The effectiveness of a crash cell can significantly impact the overall safety ratings of a vehicle. By utilizing robust materials and innovative design paradigms, manufacturers can reinforce chassis structures to improve their capacity to protect passengers.

As technology advances, so too do the techniques employed for chassis reinforcement. This article delves into the latest crash testing methodologies and the cutting-edge technologies employed in the reinforcement of chassis systems, showcasing how these developments contribute to a safer driving experience. Understanding these elements not only highlights the importance of rigorous testing but also underscores the continuous efforts in the automotive industry to prioritize occupant safety.

Understanding Crash Test Methodologies for Vehicle Safety Evaluation

Crash testing is an essential aspect of vehicle safety evaluation, providing critical insights into how vehicles behave and protect occupants during collisions. Various methodologies are employed to assess the safety of vehicles, focusing on established testing protocols and real-world scenarios.

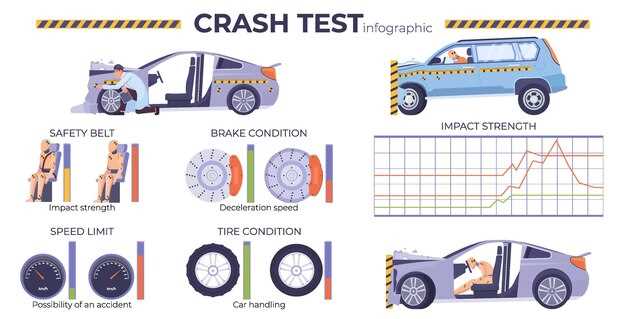

One widely recognized approach involves the use of crash test dummies, often referred to as test cells, which simulate human responses in accidents. These dummies are equipped with sensors that collect data on impact forces, deceleration, and potential injury mechanisms. This information is vital for assessing the effectiveness of safety features, such as airbags and seat belts.

Different test methodologies include frontal impact tests, side-impact tests, and rollover tests. Each method targets specific types of collisions, allowing manufacturers to identify vulnerabilities in vehicle design. Frontal tests typically involve a head-on collision with a barrier, while side-impact tests replicate scenarios where vehicles are struck from the side. Rollover tests evaluate a vehicle’s stability and the effectiveness of safety systems in preventing ejection during a rollover accident.

The results from these tests are utilized to enhance vehicle safety ratings and guide consumers in their purchasing decisions. Organizations like the National Highway Traffic Safety Administration (NHTSA) and Euro NCAP conduct standardized crash tests, providing consistent safety evaluations across various vehicle models. These ratings influence design modifications, encouraging manufacturers to prioritize occupant safety in their engineering processes.

Furthermore, advanced technologies such as computer simulations and virtual testing are increasingly integrated into crash evaluation methodologies, allowing for more comprehensive analysis and rapid prototyping of safety features. This evolution in testing processes underscores the importance of continuous innovation in enhancing vehicle safety.

Critical Techniques for Reinforcing Chassis in Automotive Design

Reinforcing the chassis is a crucial aspect of automotive design, particularly in the context of crash safety. Effective chassis reinforcement techniques significantly enhance the structural integrity of vehicles, thereby improving occupant protection during crash events.

One of the primary methods for reinforcing a chassis involves using high-strength materials, such as advanced steel alloys or composite materials. These materials offer better energy absorption characteristics compared to conventional steel, allowing the chassis to deform in a controlled manner during a crash, thereby reducing the impact forces transmitted to occupants.

Another critical technique is the implementation of strategic reinforcements through the use of additional crossmembers and support beams. These components are designed to create load paths that direct impact forces away from the passenger cell. By optimizing the layout of these reinforcements, engineers can enhance overall rigidity while minimizing weight.

Additionally, utilizing computer-aided design (CAD) tools and finite element analysis (FEA) plays a significant role in chassis reinforcement. These technologies allow designers to simulate crash tests virtually, helping identify weak points in the chassis early in the design phase. Iterative testing through simulations enables the refinement of chassis geometry and reinforcement placement, which ultimately leads to improved crashworthiness.

Incorporating crumple zones is another effective technique. These zones are specifically designed to deform and absorb impact energy during a collision, protecting the rigid passenger cell. By designing rear and front crumple zones with optimal shapes and material compositions, automotive engineers can significantly enhance the vehicle’s ability to withstand frontal and rear impacts.

Finally, the use of robotic welding techniques ensures the consistency and quality of the connections between different chassis components. Robust joining methods increase the overall structural integrity of the chassis, contributing to improved performance during crash tests.

The Role of Safety Cells in Enhancing Passenger Protection

Safety cells are crucial components in modern vehicle design, specifically engineered to provide enhanced protection for passengers during a crash. These structures, often referred to as safety cages, are designed to absorb and dissipate energy generated during a collision, minimizing the impact on occupants.

In crash tests, vehicles equipped with advanced safety cells consistently demonstrate improved performance. The integrity of the cell helps maintain a survival space, preventing cabin intrusion that can result in severe injuries. This aspect is vital in evaluating a vehicle’s safety ratings, as regulatory agencies prioritize occupant protection in their assessments.

Safety cells are typically constructed from high-strength materials, allowing them to withstand significant forces while remaining lightweight. This balance is essential in maintaining overall vehicle performance while ensuring maximum protection. The strategic placement of crumple zones around the safety cell enables the vehicle to absorb impact energy before it reaches the passenger compartment.

Moreover, the design of safety cells incorporates various features such as reinforced pillars and cross members, which further enhance their structural integrity. These reinforcements work in synergy with other safety technologies, such as airbags and seatbelt systems, to create a comprehensive approach to passenger safety.

In conclusion, the role of safety cells is paramount in enhancing passenger protection. Their ability to maintain structural integrity during crash tests not only safeguards occupants but also reflects innovative engineering practices in the automotive industry. With ongoing advancements, safety cells will continue to evolve, leading to even more effective passenger protection in the future.